Zinc plating is one of the few basic electroplating processes in our plating business, we can offer a few ranges of colored finishing to suit our customer’s requirements. With Zinc-plated goods being significantly more sensitive to environmental factors, we have established precise control over our passivation lines to ensure the continuous production of quality goods.

| Process | Specs | Process Classification | Tank Size (L) x (W) x (H) mm | Locations |

|---|---|---|---|---|

| Zinc Plating | ASTM-B633 / QQ-Z-325 | Zinc Blue | 1200 x 900 x 900 |

Singapore |

| Zinc Yellow | 850 x 700 x 900 |

|||

| Zinc Black | 850 x 400 x 900 | |||

| Zinc Blue # 1 | 1000 X 900 X 800 | Penang | ||

| Zinc Blue # 2 | 2500 X 250 X 800 | |||

| Zinc Blue # 3 | 2200 X 1000 X 1300 | |||

| Zinc Blue # 4 | 1000 X 900 X 800 | |||

| Zinc Black | 650 X 550 X 650 | |||

| Zinc Yellow | 1000 X 900 X 800 | |||

| Auto Line 1 (Blue / Yellow) | 2000 X 340 X 1000 | |||

| Auto Line 2 (Blue / Yellow ) | 1500 X 400 X 1000 |

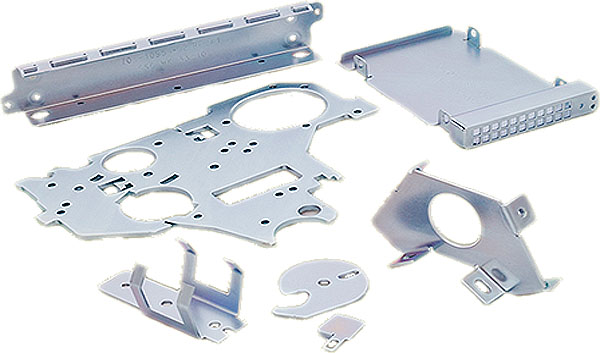

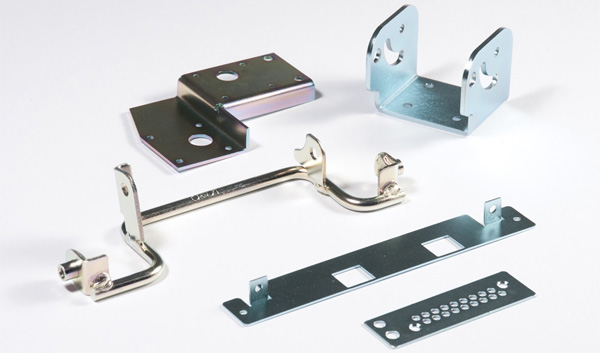

Zinc plating is the most common, low cost; an electroplated coating that is normally used for ferrous components to promote corrosion resistance. The coating can be colored to give gold; black or olive drab coatings by post-dip. The reasonably low cost, protective nature, and attractive appearance of zinc make it a popular coating for nuts, bolts, washers, sheet metal stampings, and automotive components, such as interior parts and gas filters. Zinc also serves as an effective undercoat for paints when high corrosion performance and adhesion are required.